Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

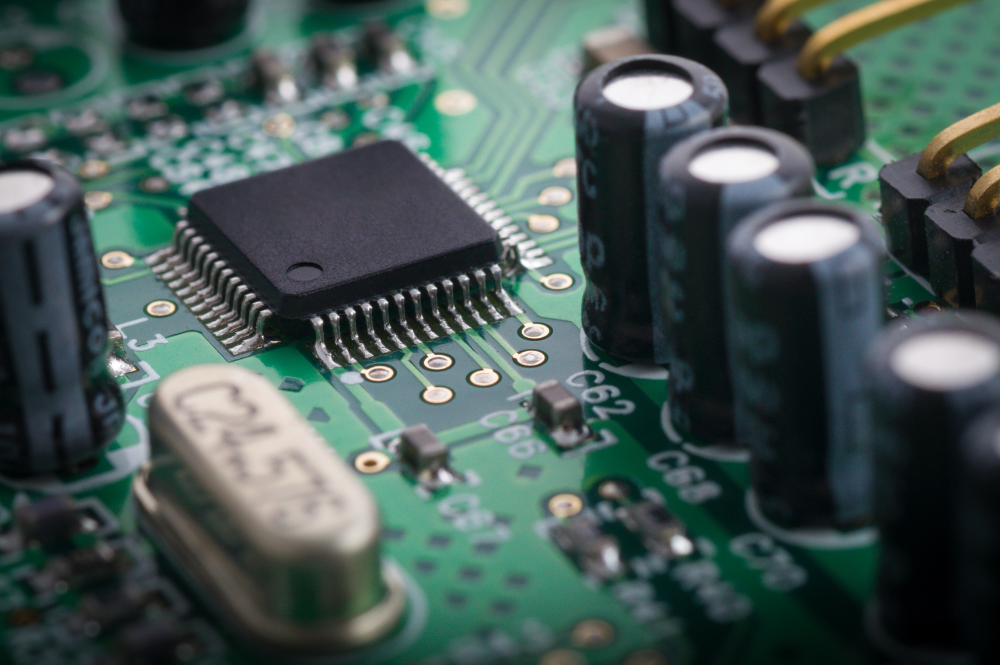

The electronics industry has evolved rapidly, thanks in large part to the adoption of surface mount technology PCB solutions. By allowing components to be mounted directly onto the surface of printed circuit boards, SMT has transformed how PCBs are designed and manufactured. Compact, fast, and cost-effective, SMT has become the preferred method for most modern PCB assemblies. In this article, we’ll explore how SMT changed the industry, highlight the key SMT assembly benefits, and compare it with traditional through-hole technology.

Surface mount technology PCB assembly involves placing components directly onto the surface of the board, as opposed to inserting leads through holes as done in through-hole assembly. SMT components are smaller, lighter, and typically come with short or no leads. This allows for more compact circuit designs and higher component density on both sides of the board.

One of the most significant SMT assembly benefits is the ability to create smaller, more lightweight devices. With minimal space required for each component and no need for drilled holes, designers can maximize the use of PCB real estate. This is critical in industries like consumer electronics, medical devices, and wearables, where compact form factors are essential.

SMT is well-suited for automated processes, making it highly efficient for mass production. Pick-and-place machines can place thousands of components per hour with pinpoint accuracy. This automation drastically reduces labor costs and production time, making SMT ideal for high-volume manufacturing.

The smaller size of SMT components not only reduces material costs but also enables the use of smaller PCBs and simpler packaging. Since the assembly process is faster and more automated than through-hole assembly, overall production costs are significantly lower.

With shorter lead lengths and better solder joint connections, SMT components often provide better electrical performance. The reduced inductance and resistance lead to faster signal transmission and improved overall reliability, especially in high-frequency or high-speed applications.

While surface mount technology PCB assembly dominates modern electronics, through-hole technology still has its place—particularly in applications requiring strong mechanical bonds or high-power components. Here's a detailed comparison:

Ultimately, SMT offers greater advantages for most modern applications, especially where miniaturization, speed, and cost control are priorities. However, hybrid designs using both SMT and through-hole components are also common when both electrical and mechanical needs must be met.

SMT assembly benefits go beyond just cost savings. By allowing for more complex and compact circuit designs, SMT opens the door for innovation in every sector of electronics. From smartphones and tablets to advanced automotive control systems and IoT devices, SMT enables technologies to evolve at the pace of modern demand.

At Creative Hi-Tech, we offer advanced surface mount technology PCB services tailored to meet the needs of a variety of industries. Whether you require quick-turn prototyping or full-scale production, our SMT capabilities ensure high-quality results delivered on time.

Contact us today at 224-653-4000 or email sales@creativehitech.com to learn how our SMT solutions can help bring your next product to life.

SMT allows for compact designs and high-speed automated production, making it ideal for modern electronics.

SMT offers faster assembly, smaller components, and lower costs, while through-hole is better for mechanical strength and high-power applications.

Industries like consumer electronics, automotive, telecommunications, and medical devices benefit significantly from SMT assembly.

Yes, many PCBs use a combination of SMT and through-hole components for electrical and mechanical needs.

Yes, SMT components offer excellent electrical performance and are commonly used in high-speed and high-frequency circuits.