Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

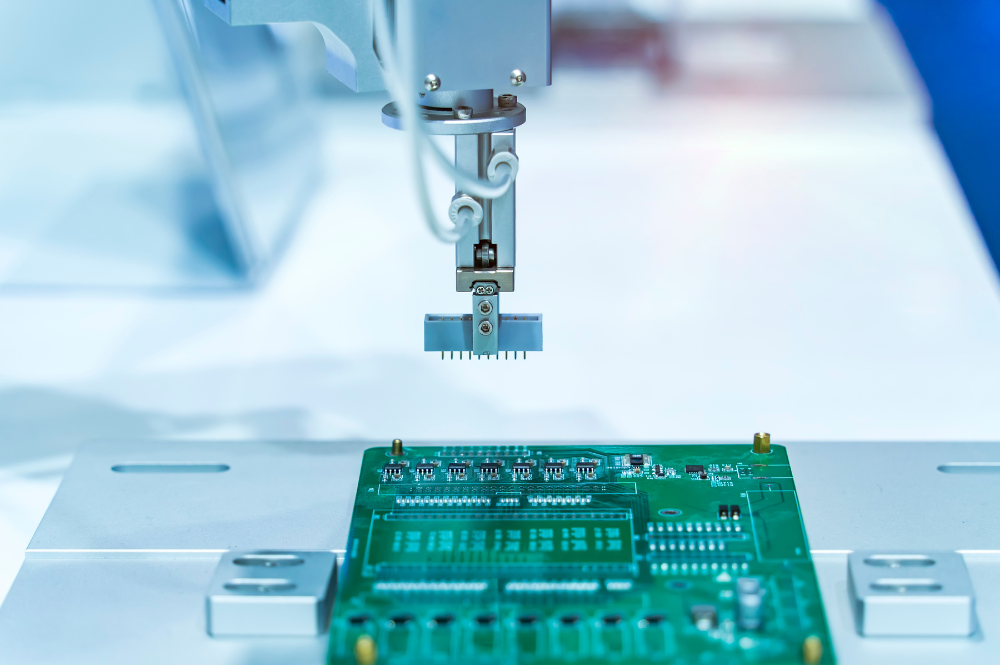

A product launch can make or break a company in today's fast-paced, innovation-driven world. Whether you’re building the next wearable tech gadget or a game-changing medical device, the speed at which your product hits the market has become just as important as its performance. This is where quick turn PCB assembly becomes more than a convenience; it’s a competitive edge.

Businesses are no longer waiting weeks for circuit board prototyping. Fast PCB production is streamlining the development process, empowering engineers and manufacturers to iterate faster, adapt to market demands, and scale with confidence.

Quick turn PCB assembly supports fast prototyping and speeds up product testing cycles.

Fast PCB production allows businesses to pivot and respond to evolving market needs.

Seamless transition from prototyping to full-scale production ensures efficiency.

Quick turnaround times don’t mean sacrificing quality or compliance.

Understanding Quick Turn PCB Assembly

Quick turn PCB assembly refers to the rapid production and assembly of printed circuit boards, usually within 24 hours to a few days. It’s built for speed without cutting corners. Traditional PCB production might stretch into weeks, but fast PCB production services shrink that timeline dramatically.

This approach is particularly valuable for industries where agility is non-negotiable: aerospace, consumer electronics, automotive, medical devices, and beyond. When development windows are short and market timing is critical, quick turn PCB assembly becomes the secret weapon for hardware teams.

Speed unlocks opportunity. In the prototyping phase, engineers test ideas, catch design flaws, and fine-tune performance. But every delay compounds. Waiting weeks for PCB revisions can slow innovation and inflate development costs.

Fast PCB production enables teams to experiment rapidly. When boards arrive in days rather than weeks, engineers can move from concept to validation with far less friction. This iterative rhythm allows startups and enterprise teams alike to sharpen their designs and bring only the best versions to market.

With quick turn PCB assembly, teams can go from napkin sketch to testable unit on a compressed timeline, accelerating the product lifecycle and reducing costly rework.

Markets don’t wait. A sudden spike in demand, emerging technologies, or shifts in consumer preferences can force immediate pivots. Businesses that can’t adapt risk falling behind.

Fast PCB production offers the flexibility to respond quickly. Need to redesign a circuit to accommodate a new chipset? Or tweak a layout due to a supplier change? With quick turn PCB assembly, these changes can be implemented and tested without upending your schedule.

This kind of responsiveness is a clear advantage in tech-driven industries. It empowers manufacturers to lead rather than lag behind.

One of the greatest strengths of quick turn PCB assembly is its scalability. What begins as a single prototype can rapidly evolve into a full production run. Partnering with a manufacturer that offers both quick turn and high-volume capabilities ensures continuity and reduces the friction of switching providers.

Fast PCB production isn’t just about speed; it’s about setting the foundation for successful scaling. By working with a partner that can flex between low- and high-volume runs, businesses reduce risks, streamline communication, and maintain quality throughout the process.

There’s a common misconception that speed sacrifices quality. But with modern equipment, skilled technicians, and tight process controls, quick turn PCB assembly can meet the same standards as longer lead-time production.

Quality assurance is baked into every phase, from solder paste inspection and automated optical inspection to in-circuit testing and functional validation. Even under tight timelines, we can ensure that every board meets specifications and complies with global standards like RoHS.

This level of quality control is especially critical in regulated sectors like healthcare and automotive, where failure is not an option.

At Creative Hi-Tech, we understand that time-to-market matters. That’s why our quick turn PCB assembly services are built to deliver both speed and precision. Whether you need single- or multi-layer boards, surface mount or through-hole components, our team is equipped to deliver high-quality assemblies within days.

We support fast PCB production at every stage—concept, prototype, and production. Our facility combines advanced automation with experienced hands-on technicians, ensuring your boards are built right the first time. From Gerber file review to final testing, we provide a smooth, responsive process that helps you stay ahead of the curve.

If your project timeline can’t afford delays, quick turn PCB assembly is your solution. Creative Hi-Tech is ready to support your next product with high-speed, high-quality PCB assembly services tailored to your needs. Contact us today to discuss your next build and discover how we can help you bring your ideas to life faster.

Typically, quick turn PCB assembly means producing and assembling boards within 24 hours to 5 days, depending on complexity and order size.

Yes. Advanced facilities can manage multi-layer boards and intricate layouts while maintaining tight timelines and quality standards.

No. Quality assurance procedures, including automated testing and visual inspection, are maintained even under fast timelines.

Submit detailed Gerber files, BOM, and assembly drawings. A manufacturer like Creative Hi-Tech can review and verify your files quickly.

Absolutely. RoHS-compliant, lead-free options are available and often preferred for environmentally responsible builds.

Yes. Working with a partner like Creative Hi-Tech ensures a smooth transition from small runs to large-scale production without disruption.