Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

Today’s electronics landscape is anything but simple. Devices are getting smarter, smaller, and more interconnected, yet the systems behind them grow more complex by the day. That’s where box build PCB assembly steps in, offering manufacturers a way to manage and simplify intricate designs while maintaining efficiency, quality, and scalability.

Whether you're assembling advanced aerospace components, medical equipment, or telecom infrastructure, you need more than just individual circuit boards. You need integrated, ready-to-deploy electronic manufacturing solutions and you need them fast.

Box build PCB assembly integrates sub-assemblies, enclosures, and software for a complete product solution.

Streamlined in-house processes reduce production time and cost.

Custom assembly options protect fragile components and adapt to complex applications.

Compliance with industry standards ensures safety and quality across sectors.

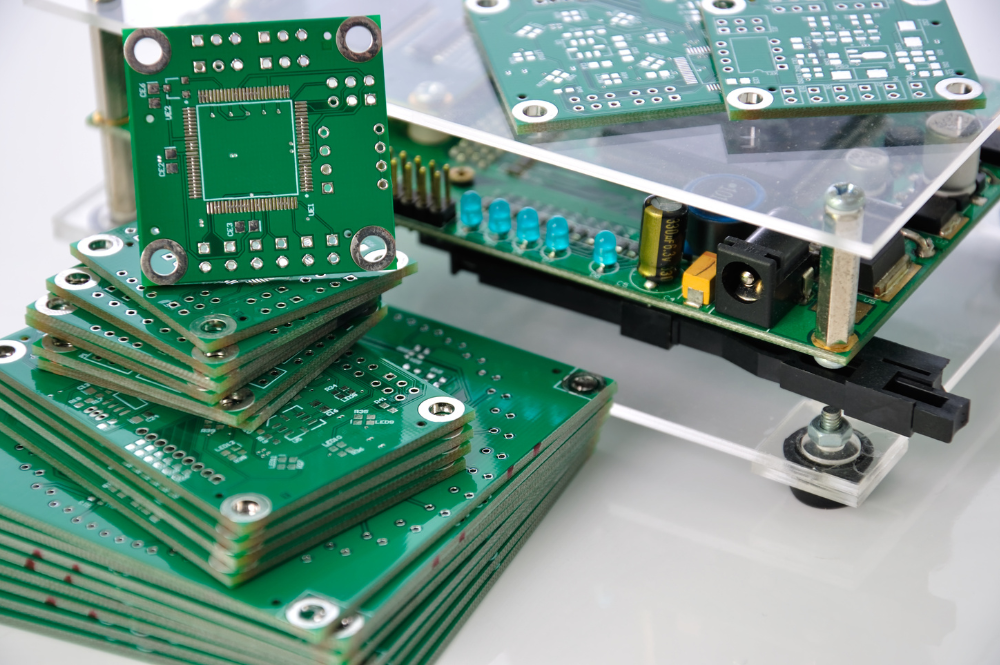

At its core, box build assembly (also known as system integration) involves more than just a populated PCB. It’s the final phase of turning a bare board into a fully functional product. This includes installing the PCB into an enclosure, wiring internal components, loading software, and testing the unit for functionality.

Unlike standard PCB fabrication, box build PCB assembly covers a broader scope. Think of it as a full-package solution that combines mechanical, electrical, and logistical expertise into one seamless process. For manufacturers navigating tight deadlines and complex configurations, this level of integration is a game-changer.

One of the strongest benefits of box build PCB assembly is the efficiency it brings to the table. By performing every step of the assembly process in-house—from sub-level assembly and system integration to packaging and traceability—manufacturers like Creative Hi-Tech eliminate the bottlenecks associated with outsourcing.

With streamlined workflows, automated conveyors, and customized robotics, fast turnaround doesn’t have to mean compromised quality. These time-saving methods don’t just boost delivery speeds; they also reduce overall production costs by minimizing rework and miscommunication.

This model of fast, cohesive service delivery is especially critical in sectors like automotive and aerospace, where lead times are shrinking but expectations are climbing.

Complex electronics often involve more than one PCB, not to mention a maze of wires, connectors, and firmware. The beauty of an expertly executed box build PCB assembly is that it ensures every one of those moving parts works together as a unified system.

Creative Hi-Tech takes this integration a step further with software loading, functional and environmental testing, and configuration services. Whether your final product needs to survive extreme heat, resist contaminants, or simply boot up flawlessly out of the box, each component is validated before it ships.

The result? Fewer on-site issues, smoother installations, and peace of mind for your engineering and quality assurance teams.

Every project has its quirks. Whether it's a ruggedized display for a military vehicle or a compact control panel for industrial automation, cookie-cutter solutions just don’t cut it. That’s why customization plays a pivotal role in modern box build services.

Electronic manufacturing solutions today must be versatile and Creative Hi-Tech delivers. Projects range from terminal blocks and turnkey enclosures to displays and control panels. These aren’t off-the-shelf builds; they’re tailored integrations that meet real-world challenges in real-time.

Need extra shielding from EMI? Or a design that holds up in a moisture-heavy environment? Custom system integration can account for these variables and more.

High-performance electronics demand high-reliability production. That’s why Creative Hi-Tech’s box build PCB assembly process adheres to strict industry standards, including IPC-WHMA-A-610 and IPC-CC-830B compliance.

But standards alone aren’t enough. That’s where inspection, testing, and validation come into play. Before leaving the facility, each product undergoes rigorous checks—ranging from final functional tests to environmental simulations—ensuring it meets application-specific requirements.

Add in product traceability and barcode labeling, and you have a solution that’s built for transparency and long-term reliability.

Choosing a partner for your box build PCB assembly isn’t just about getting parts assembled; it’s about choosing a team that understands the full scope of your project and can execute with precision.

Here’s why companies across aerospace, defense, telecom, and medical tech trust Creative Hi-Tech:

All-in-one solutions: Sub-assemblies, software installation, testing, and shipping handled under one roof.

Industry versatility: Expertise across high-stakes industries with tight regulatory requirements.

Rapid production: Automated workflows that support fast delivery timelines without sacrificing quality.

Quality-first approach: Certified processes, traceability, and thorough testing on every unit.

Custom-fit builds: Adaptable services designed to meet the exact environmental, functional, and form-factor needs of your system.

To simplify your next complex assembly, trust the team that offers complete electronic manufacturing solutions with speed, accuracy, and care. Contact Creative Hi-Tech today to discover how our box build PCB assembly services can accelerate your production cycle without compromising quality.

It includes all tasks beyond bare PCB assembly, such as sub-assemblies, enclosures, wiring, testing, software loading, and packaging.

Absolutely. Custom designs are available for industries including aerospace, defense, telecom, and healthcare, tailored to specific use cases and environments.

In-house processes and automated assembly tools allow Creative Hi-Tech to manage projects from start to finish, eliminating vendor delays and optimizing lead times.

Each product undergoes functional, environmental, and final testing to ensure it performs as expected under operational conditions.

Yes; the company adheres to industry and environmental standards, ensuring safe, compliant assemblies for global applications.