Newsletter Sign Up

Subscribe to get the latest news and updates. No spam , we promise.

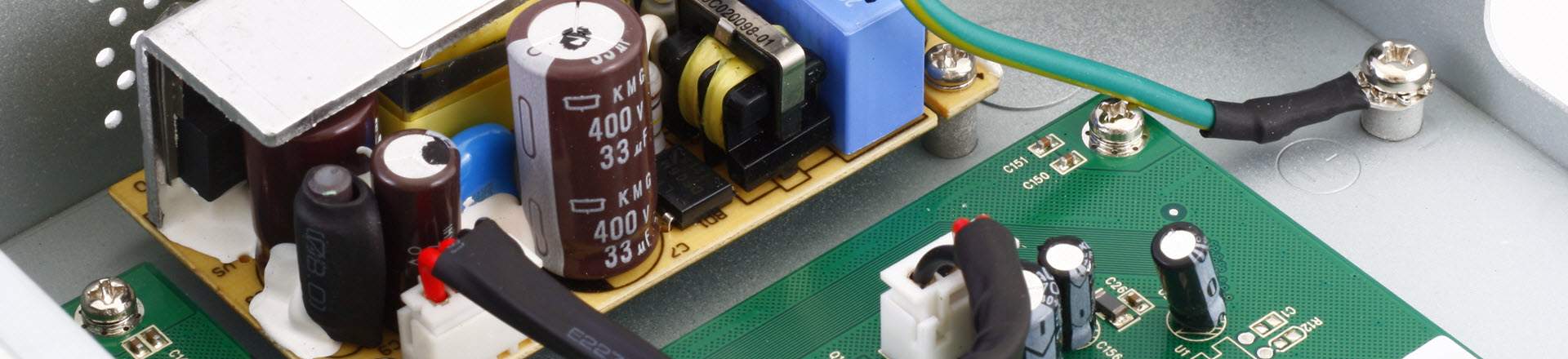

We design and assemble ten different types of PCBs for our clients. We even have the capability to create custom PCB assemblies based on client requirements.

As a leading PCB assembly service provider, Creative Hi-Tech Ltd. (CHTL) strives to meet standard and custom printed circuit boards requirements of every customer.

Since our inception, we have been able to create circuit boards that have met the application needs of clients from diverse industries. These include aerospace, medical, telecom, and computer and business electronics.

As our organization has grown over the years, so has our printed circuit board offerings. We have the capability to assemble ten different types of industrial PCBs. The details of each type are provided below for your perusal.

Rigid PCBs : These circuit boards are designed using copper layers, and insulating FR4 glass epoxy panels. Rigid printed circuit boards are known for their compact size, immunity to movement, and ability to perform without creating excessive noise.

Burn-in PCBs : Printed circuit boards of this type undergo a burn-in process to ensure component reliability, and long-lasting PCB performance. High grade versions of FR4 (high Tg FR4) and polyimide are utilized in creating this PCB. All active and passive components are chosen based on their ability to comply with high temperature requirements.

Flexible PCBs : Also known as flex circuits, these circuit boards are assembled using flexible materials. They can be used to link circuit boards and remote devices, and are a great alternative to rigid boards. Flexible PCBs provide benefits of dense circuitry, elimination of mechanical connectors, and reduced PCB size and weight.

Multilayer PCBs : These circuit boards comprise complex designs, and are mainly used in intricate applications. Multilayer PCBs are the ideal choice when a PCB Design for Manufacturing (DFM) solution is required. The circuit board stack up configuration of this PCB improves its performance in an application.

Lead-free PCBs : For these PCBs, Creative Hi-Tech utilizes laminate materials with a higher thermal decomposition temperature (Td). This helps the circuit board maintain its design during long assembly dwell times. The use of Td laminates also increases the board’s ability to withstand high temperatures. Our PCBs have the capability to provide exemplary performance in applications with temperatures ranging from -49ºF to 293ºF.

Single Sided PCBs : Single sided PCBs are designed only with a single copper layer. These circuit boards are ideal when issues related to etching, PTH, alignment, routing, etc. need to be avoided.

Double Sided PCBs : As the name suggests, the circuit boards are designed with two or more copper layers. Double sided PCBs are perfect for manufacturing according to standard parameters. Their designs allow for a smooth transition from prototyping to assembly.

Box Build Assemblies : These products can be assembled using both SMT and PTH technologies. They can be designed with simple and complex metal frames. To reduce overall costs, pre-tested sub-assemblies can be provided as an option to customers. Box build assemblies are ideal for applications involving electro-mechanical machines, and automated equipment.

High Reliability PCBs : As the name suggests, these PCBs are designed to ensure inimitable and reliable performance. We at CHTL design our high reliability PCBs with perfect circuitry and hole wall thicknesses. Also, we offer intricate surface treatment and cleanliness that exceed IPC specifications to ensure improved performance compared to other PCB types.

High Temperature PCBs : These PCBs are specifically designed for applications where they will be exposed to extreme thermal loads, and high operating temperatures. We recommend materials with high glass transition temperatures (Tg). This allows the high temperature PCBs to have immense delamination durability.

At CHTL, we have the capability to assemble printed circuit boards using a variety of materials. Our printed circuit board products and processes comply with the regulations of IPC, and RoHS. If you would like to know more details about our product assembly offerings, please contact us, or send us a Request for a Quote.

Do you need an instant PCB assembly quote for an upcoming project? Please use the advanced online PCB calculator to get competitive pricing for your requirement.